Distribution of planned independent requirements can be key in getting your MRP results exactly right. This post is about how to break down your Sales and Operations Plan and schedule it for MRP. E.g. Assume your SOP is planned in monthly buckets, but you plan your production in weekly buckets and you use forward scheduling for your production orders. In this case you want independent requirement quantities show on the first day of the week. Another example: since you plan production on a daily basis you want your monthly forecast spread out on a daily basis throughout the month. Distribution of planned independent requirements can help you achieve this.

MC44 – Inventory Turnover (2)

In MC44 – Inventory Turnover (1) I explained the concept of Inventory Turnover and how it can be used. In this post I will explain the transaction itself. The transaction is mostly self-explanatory, but there is one option of particular importance.

Forecasting – Copy history

In forecasting it is fair to say that most forecast models only sensibly apply to high volume materials and that for low volume materials (although specific models exist)more manual intensive forecasting practices apply. A lot of customers prefer to use historical data one on one for the future predictions: May 2008 – 120 boxes sold hence May 2009 -120 boxes sold, June 2008 – nothing sold hence June 2009 also nothing sold, and so on. In a lot of situations it is desirable to manually adjust some of the forecast values. So if you wish to use last year’s actuals as your forecast for the upcoming year you can do the following:

MC44 – Inventory Turnover (1)

Inventory Turnover is a prominent KPI in a lot of businesses. This post will give you some understanding on the concept. In another post I will give details on how the SAP report MC44 can be used to measure inventory turns and what data is used to calculate this ratio.

Formula

Inventory Turnover = Cost of Goods Sold (COGS) / Average Inventory at value

If you are not familiar with the term Cost of Goods Sold, this is the cost of your revenues.

Average Inventory is measured in value and not in volume.

If you divide both elements you know how often you sold you’re average inventory. “So what?” you ask. I will explain next.

MD04 – Export planning to Excel

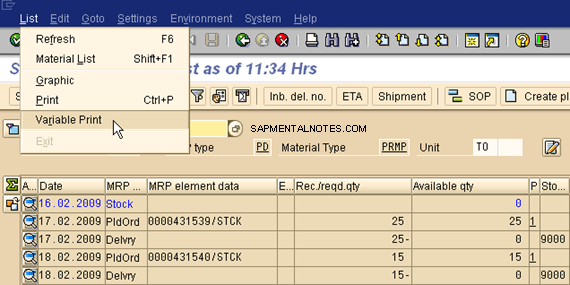

MD04 Print variant

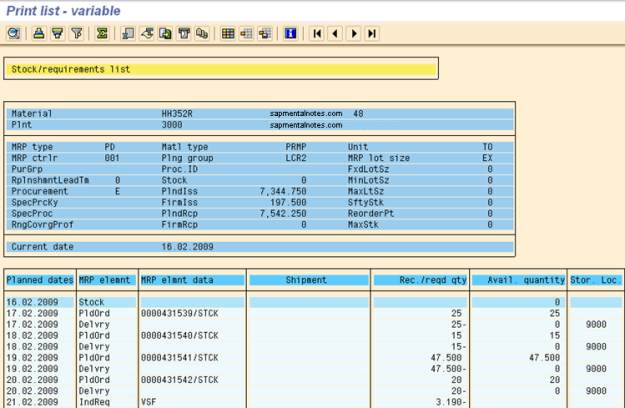

Immediately a new overview opens up that may look less attractive than the overview you are used to. On the screen ‘Print list – variable’ you can change the lay-out and save it as a variant like you are used to in standard SAP reporting.

MD04 printlist lay-out

To get the best Excel results export the report directly to an Excel table, as opposed to first store it as a local file and then open it in Excel. This way the lay-out is optimized for direct filtering and sorting.

This is all there is to it. Sometimes SAP life is that easy.

Batch determination for IM

This blog offers a quick guide on how to use standard SAP Batch Determination for a material transfer. For an internal goods movement we need SAP to pick the batch from stock with the earliest Shelf Life Expiration Date (SLED). We don’t want our fresh products terminate themselves from stock…

1. For this we will be using standard IM search strategy ME001 – Standard Search Procedure.

IMG > Logistics > Batch Management > Batch Determination and Batch Check > Batch Search Procedure Definition > Define Inventory Management Search Procedure

IM Search Procedure

Unblock SD Documents

This post is an extension to a previous post on Credit Checks exceeded. When you are in a testing environment it is common that it’s difficult to quickly process sales orders and/or deliveries because the credit check is exceeded for a customer. Credit is building up, since so many sales orders and deliveries are entered but are usually not going through the whole process including payment processing. To quickly clear a blocked order got to transaction VKM1.

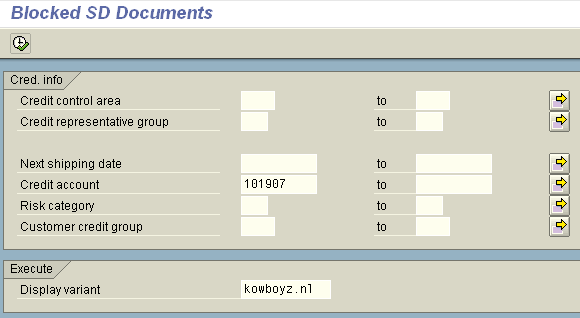

VKM1 – Blocked SD Documents

In the main screen enter a common criterion like Credit account (usually sold-to) and hit the execute button (F8). In the report screen that follows, select the document to be unblocked and press the green flag button followed by saving the approval. Now you can continue processing the order or delivery.

SQVI – Create quick report

In an earlier post I promised to give a quickguide to creating a query in SAP based in transaction SQVI. I’m going to show you how you can quickly build a custom report for reporting Sales Schedule Lines based on different filter criteria and multiple tables (VBAK, VBAP and VBEP: header, item and schedule line data resp.):

Test standard LIS analyses with different source versions

There are wonderful reports available in standard SAP’s Information Structures (E.g. MCxx reports). It can be so cruel though when data gets corrupted. You usually end up comparing report figures with whatever reasonable value you find elsewhere in SAP. If you want to be sure about the Information Structure’s reliability it is worthwhile to update an infostructure (say S021 – Production Order), store it under a temporary version ‘&(1’, and finally call this test version in a report that default uses version ‘000’.

To call up another version than ‘000’ go to System > User profile > User parameters and enter the parameter ID ‘MCR’ with the value ‘X’.

Now if you call up a standard analysis like MCP3 – Production Order Analysis a new field is visible for version selection. See picture below.

The major benefit of this procedure is that you don’t have to backup/delete current production data in version ‘000’.

It is also possible to compare the current version ‘000’ with the new test version going to Menu > Edit > Comparisons > Planned/Actual…

Source list benefits

A good way of tightening authorization in your procurement organization is using mandatory source lists. In a previous post I explained how you can use source list in a central procurement organization together with MRP. Setting source list as a requirement for procurement you block any Purchase Order from being created if the material/vendor combination is not known to the source list for the purchasing organization, purchasing group and, or plant. This is excellent if rogue buying (i.e. buying without taking advantage of negotiated company discounts) in SAP is an issue in your company. This is how you implement mandatory source lists in your organization: Continue reading